Table of Contents

Stock Location Management Module

Currently within Datafile Stock Locations are managed in one of two ways. The primary option, where locations are geographically based, is to include in the stock code a prefix for the geo-location –i.e. CH for Chester, DI for Didcot and so on. The secondary option, where you’re looking to track bin locations would be to use the batch tracking facility –as each item is booked in a location is assigned to it, as you move items through the warehouse and the bin location changes then transfers are created to move the stock between bins.

When using a location prefix, it may be more difficult to see the overall stock a single place and when using Batch Locations not all stock items may need a Batch or Serial code but one would need to be created regardless.

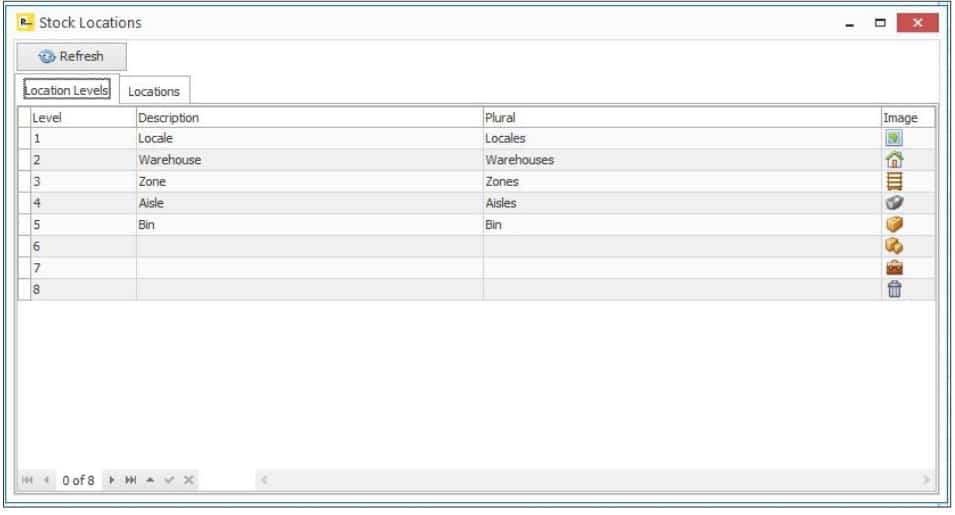

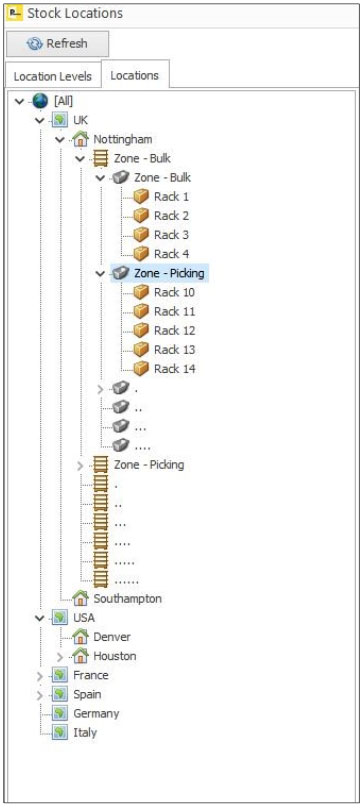

A new module,currently in development,allows for a more comprehensive solution. The stock item will be the SKU itself and the values recorded will encompass all the geo-locations and bin locations. The bin locations will be flexible –allowing for new bin locations to be created automatically based on a matrix of allowed locations.

As stock is booked in it can be automatically assigned either a holding or receiving bin location –transfers can then be used as it’s put away.

As sales orders are entered then default geo-locations can be assigned during order entry so physical checks can be performed against the geo location but can also flag up, if insufficient stock, that other geo locations do hold stock and you can select this location in preference. Stock picking notes will suggest the available location(s) on a FIFO basis

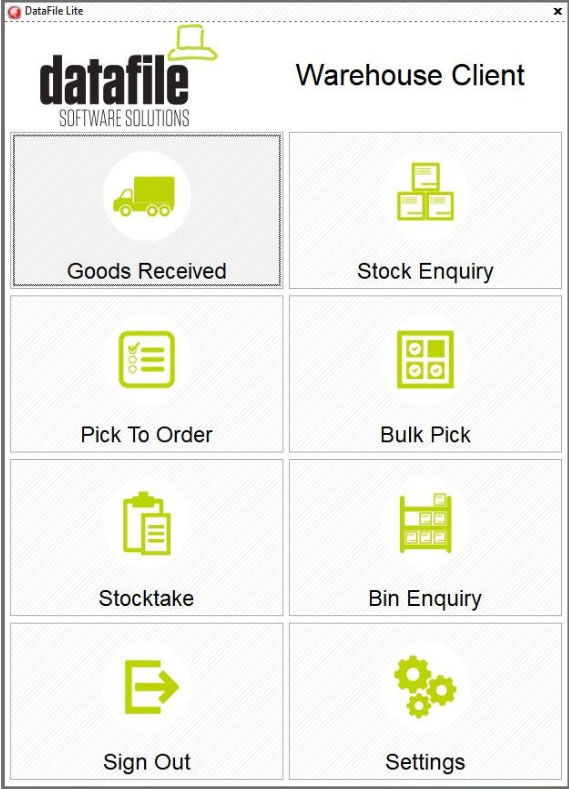

Warehouse Client

Datafile are also currently developing a separate “lite” Datafile application to run on a Windows tablet device. The lite application will be designed initially around Warehouse requirements and can be used in conjunction with the new stock location management options but can also be used with the existing functionality.

Goods Received – this option will prompt for an order reference and show the order lines awaiting delivery.

If the tablet has either a built in Bar Code scanner or peripheral USB scanner attached,then an item can be scanned,and the order line selected automatically.The operator would then confirm the quantity received and this would update the standard Datafile application in real time.

Stock Enquiry – this option will prompt for the stock code (which can be scanned or searched for in the normal manner) and display the current stock holding and locations held.

Pick to Order – operates on a single order and prompts for an order reference and shows the lines to be picked and the available and suggested locations. As with the Goods Received option an item can be scanned and the order line selected automatically, the picked quantity then confirmed.

Bulk Pick – operates on multiple orders at once allowing for ‘pick routes’ to be assigned to operatives for improved picking speeds.

Stock Take – allows for the entry of stock counts.Bin Enquiry–allows for the entry/scan of a bin location and shows the stock items assigned to that bin.